NGV-REFUELING COMPRESSOR STATIONS

OJSC Penzkompressormash has developed NGVRC station designed for various purposes:

The equipment currently supplied by our company is a set of ready-to-operate modules designed for installation at a NGVRCS site.

OJSC Penzkompressormash delivers a complete set of equipment for NGV refueling compressor stations in strict compliance with the specifics of each customerвАЩs project. Comprehensive project implementation is also available, including design and commissioning operations with subsequent service maintenance.

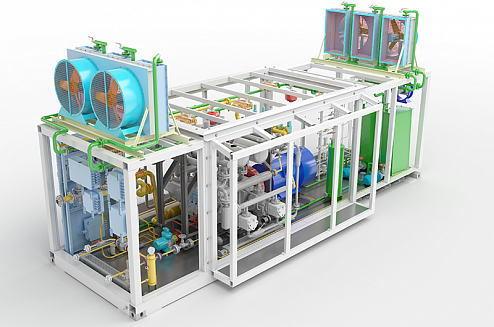

Figure. A standard structure of a NGVRC station by OJSC Penzkompressormash

Each set of NGVRC station equipment manufactured by OJSC Penzkompressormash, for the typical version, includes:

1. Gas pressure reduction assembly.

2. Inlet valves assembly.

3. Commercial metering unit.

4. Compressor refueling module (MKZ), complete.

5. Operator room with ancillary facilities (12x9m):

NGVRCS control and protection system;

electric drive control system;

complete equipment control system;

power distribution system.

6. Pressure compensator unit.

7. Gas filling equipment.

8. Inter-unit piping system.

9. Inter-unit cabling system.

10. Drainage tank.

11. General SPTA.

The specific supply set shall be specified by the customer in consultation with the designer at filling of the questionnaire and preparation of technical and commercial proposal.

MKZ-500

Purpose: refueling of vehicles with compressed gas at low gas requirements.

Specifications:

-

capacity of 280/600 nm3/h

-

suction line gas pressure of 2.0/4.0 kg/cm2

-

discharge line gas pressure of 250 kgf/cm2

-

вАҐ average number of filling cycles per day of 180

| Station model | Inlet pressure (gage), kgf/cm2 | Capacity, m3/min | Number of filling cycles per day | Dimensions (mounting dimension), LxWxH, mm |

|

MKZ-500.251.01 |

–і–Њ 0,05 | 540 | 180 | 7000—Е2450—Е2896(4420) |

| MKZ-500.7-251.01 | 3-6 | 280...500 | 165 | 7000—Е2450—Е2896(4420) |

MKZ-900

Purpose: refueling of vehicles with compressed gas at low gas requirements.

Specifications:

-

capacity of 420/990 nm3/h

-

suction line gas pressure of 2.0/4.0 kg/cm2

-

discharge line gas pressure of 250 kgf/cm2

-

average number of filling cycles per day of 300

| Station model | Inlet pressure (gage), kgf/cm2 | Capacity, m3/min | Number of filling cycles per day | Dimensions (mounting dimension), LxWxH, mm –Љ |

| MKZ-600.4-251.01 | 1,0-3,0 | 290...600 | 200 | 7000—Е2450—Е2896(4420) |

| MKZ-600.13-251.01 | 6-12 |

290...560 |

185 | 7000—Е2450—Е2896(4420) |

| MKZ-900.251.01 |

–і–Њ 0,05 |

890 | 295 | 7000—Е2450—Е2896(4420) |

| –Ь–Ъ–Ч-900.2-251.01 | 0,05...1,0 | 480...920 | 300 | 7000—Е2450—Е2896(4420) |

| MKZ-900.4-251.01 | 1,0-3,0 | 420...910 | 300 | 7000—Е2450—Е2896(4420) |

| MKZ-900.7-251.01 | 3-6 | 520...910 | 300 | 7000—Е2450—Е2896(4420) |

| MKZ-900.13-251.01 | 6-12 | 500...900 | 300 | 7000—Е2450—Е2896(4420) |

| MKZ-900.13-251.02 | 6-12 | 500...900 | 300 | 7000—Е2450—Е2896(4420) |

| MKZ-900.41-251.01 | 20...40 | 210...900 | 300 | 7000—Е2450—Е2896(4420) |

MKZ-1200

Purpose: refueling of vehicles with compressed gas at low gas requirements.

Specifications:

-

capacity of 480/1270 nm3/h

-

suction line gas pressure of 2.0/4.0 kg/cm2

-

discharge line gas pressure of 250 kgf/cm2

-

average number of filling cycles per day of 400

| Station model | Inlet pressure (gage), kgf/cm2 | Capacity, m3/min | Number of filling cycles per day | Dimensions (mounting dimension), LxWxH, mm |

| MKZ-1000.4-251.01 | 1,0...3,0 | 480...990 | 330 | 8000—Е2450—Е2896(4420) |

| –Ь–Ъ–Ч-1000.4-251.01 | 1,0...3,0 | 480...990 | 330 | 8000—Е2450—Е2896(4420) |

| MKZ-1200.7-251.01 | 3-6 | 570...1186 | 395 | 8000—Е2450—Е2896(4420) |

| MKZ-1300.7-251.01 | 3-6 | 700...1270 | 420 | 8000—Е2450—Е2896(4420) |

| MKZ-1250.13-251.01 | 6-12 | 660...1250 | 415 |

8000—Е2450—Е2896(4420) |

| MKZ-1250.13-251.02 | 6-12 | 640...1230 | 410 | 7000—Е2450—Е2896(4420) |

| MKZ-1200.61-251.01 | 30-60 | 500...1200 | 400 | 8000—Е2450—Е2896(4420) |