LOW-PRESSURE PLANTS

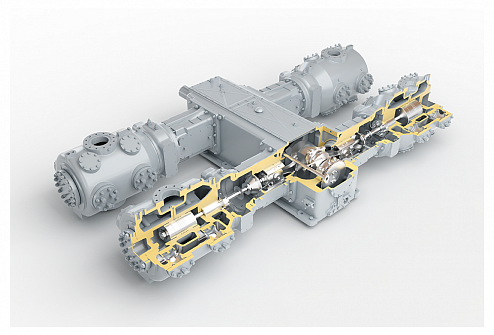

DESIGN FEATURES:

-

The opposed design of these compressors enables maintenance of a mutual balance between piston and inertial forces acting in the opposite rows, thus greatly increasing the operation speed and reducing the weight of the compressor and foundation.

-

Due to the use of thin-walled liners in journal bearings, the plants require no adjustments at shaft installation and no re-adjustments or alignment during operation, while demonstrating extended bearing life.

-

These plants are equipped with an automatic control system that controls its key parameters, alarms and locks, as well as with a staged automatic capacity control system.

-

Reduced power consumption per unit of capacity in these plants is due to the improved motion mechanism, specific compressor gas dynamics and the use of globe valves.

Installation operations required have been minimized, while the use of special preservation procedures enables compressor start-up without depreservation, thus significantly reducing the compressor commissioning time.

The use of special equipment in the manufacture of such compressor units ensures high accuracy and interchangeability of parts.

Compressor plant automation systems allow minimizing the required operating personnel.

| Name | Motor power, V | Motor voltage, V | Initial absolute pressure, kgf kgf/cm2 | Weight, kg | Dimensions: LxWxH mm | Final absolute pressure, kgf kgf/cm2 | Capacity, m3/min |

|---|---|---|---|---|---|---|---|

| CA-48.3-204.01 | 380 | 160 | 1 | 3500 | 2770—Е1480—Е1150 | 3 | 48 |

| CA-54.3-204.01 | 380 | 380 | 1 | 4100 | 2990—Е1500—Е1070 | 3 | 54 |

| 4–Т–Ь10-200/2,2–Ь | 6000;10000 | 630 | 1 | 15350 | 5000—Е6160—Е2330 | 3,2 | 200 |

| 2–Т–Ь10-100/2,2 | 6000;10000 | 315 | 1 | 8200 | 5000—Е4700—Е2750 | 3,2 | 100 |

| –°–Р-8,4-202,5.01 | 380 | 90 | 1 | 2500 | 1400—Е2050—Е1850 | 4 | 7,6 |

| 4–Т–Ь10-150/3,1 | 6000;10000 | 630 | 1 | 15350 | 5000—Е6160—Е2330 | 4,1 | 150 |

| 4–Т–Ь10-150/3,5 | 6000;10000 | 630 | 0.84 | 21400 | 5000—Е7000—Е3500 | 4.5 | 150 |

| 4–Т–Ь10-120/9 *** | 6000;10000 | 800 | 1 | 17080 | 5180—Е4430—Е3000 | 9 | 124,5 |

| 4–Т–Ь10-110/9 (* ***) | 6000;10000 | 630 | 1 | 18700 | 5400—Е5900—Е3150 | 9 | 110 |

| 4–Т–Ь10-100/9 *** | 6000;10000 | 630 | 1 | 17080 | 5180—Е4430—Е3000 | 9 | 103 |

| 2–Т–Ь10-63/9 *** | 6000;10000 | 400 | 1 | 8810 | 3500—Е44002820 | 9 | 63 |

| 2–Т–Ь10-50/9 *** | 6000;10000 | 315 | 1 | 8810 | 3500—Е4400—Е2840 | 9 | 51,5 |

| CA-10.9-2–Р2.01 | 380 | 75 | 1 | 2800 | 1670—Е1260—Е1700 | 9 | 12 |

| CA-14.9-202,5.01 | 380 | 90 | 1 | 3000 | 1400—Е2200—Е1750 | 9 | 14,7 |

| CA20.9-2–Р–Ч.01 | 380 | 132 | 1 | 4700 | 2370—Е1620—Е2200 | 9 | 22 |

| CA29.9-402,5.01 | 380 | 200 | 1 | 6400 | 2400—Е1800—Е1600 | 9 | 29 |

| CA-50.8-2A7.01 | 380 | 300 | 1 | 13000 | 3900—Е2500—Е3400 | 9 | 50 |

| CA-10.8-2A2.01 | 380 | 75 | 1 | 2300 | 1650—Е1330—Е1625 | 9 | 10 |

| CA-24.9-204.01 | 380 | 160 | 1 | 5300 | 2685—Е1485—Е2020 | 9 | 24 |

| CA-27.9-204.01 | 380 | 160 | 1 | 5300 | 30—Е1485—Е2100 | 9 | 27 |

| CA-30.8-2A5.01 | 380 | 200 | 1 | 7300 | 2965—Е1880—Е2490 | 9 | 30 |

*-1 - Reduced power consumption through the three-staged design;

*-2 - Supplied complete with a terminal gas cooler, a check valve and a suction filter;

*-3 - On request, supplied complete with auxiliary equipment (terminal gas cooler, air collector, suction filter, check valve)