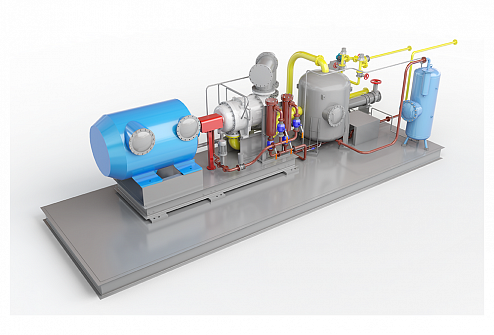

SCREW COMPRESSOR PLANTS

Purpose:

-

Compression of natural, associated, torch gas, as well as nitrogen, helium and other gases.

Specifications:

-

Performance of 2 to 100 m3/min;

-

Initial pressure 0.08 to 1.5 kgf/m3;

-

Final pressure 5 to 9 kgf/m3.

Design features:

-

Possibility of using gases containing hydrogen sulfide, carbon dioxide and others corrosive components ensured through the separation of the bearing and seals lubrication system and the injection system

-

Improved efficiency of gas transfer (compression) through performance control with the use of a frequency converter

-

Reduced commissioning time due to a modular container-type design

Screw Gas Compressor Plants

Applications:

-

oil production;

-

oil refining;

-

petrochemistry;

-

chemical industry.

Under customerвАЩs specifications, compressor plants may be supplied with parameters different from those indicated in the table.

OJSC Penzkompressormash specializes in the provision of integrated solutions for customersвАЩ tasks. In addition to equipment supplies, we offer:

-

installation supervision, start-up and commissioning services;

-

service maintenance;

-

supply of spare parts;

-

delivery of auxiliary air treatment equipment.

| Name | Rotor diameter, mm | Performance range by suction conditions, m3, at main rotor rpm of 3000 rpm/min | Max motor power, kW | Maximum inlet pressure, MPa | Maximum working pressure, MPa | Performance range by suction conditions, m3, at main rotor rpm of 1500 rpm/min |

|---|---|---|---|---|---|---|

| –Т–У-5 | 125 | 3-5 | 75 | –і–Њ 0,6 | 2,5 * | |

| –Т–У-8 | 160 | 6-8 | 132 | –і–Њ 0,6 | 2,5 * | 3-4 |

| –Т–У-15 | 200 | 9-15 | 200 | –і–Њ 0,6 | 2,5 * | 4,5-7,5 |

| –Т–У-25 | 250 | 16-25 | 400 | –і–Њ 0,6 | 2,5 * | 8-12,5 |

| –Т–У-50 | 315 | 30-54 | 800 | –і–Њ 0,6 | 2,5 * | 15-27 |

| –Т–У-75 | 350 | 45-75 | 1000 | –і–Њ 0,6 | 2,5 * | 22-37 |

| VG-100 | 400 | 70-108 | 1600 | –і–Њ 0,6 | 2,5 * | 35-54 |

* Compressors for pressures of up to 3.5 MPa may be manufactured under individual orders.

Under customerвАЩs specifications, compressor plants may be supplied with parameters different from those indicated in the table.